National Award 2022

2022 Industry Master Award - Shih-Cheng Hu

Passion and persistence to help Taiwan's semiconductor industry

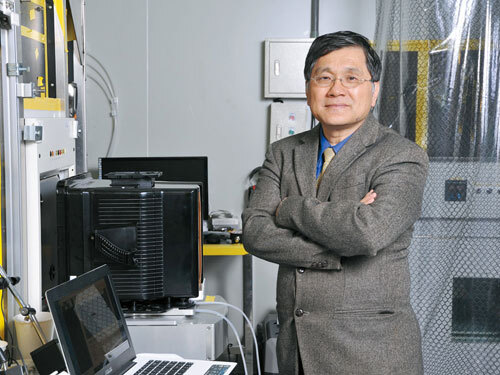

Shih-Cheng Hu, a Distinguished Professor of the Department of Energy and Refrigerating Air-Conditioning Engineering at National Taipei University of Technology, who won the Fifth National Industrial Master Award, specializes in air conditioning and pollution control for clean rooms and controlled environments, and has invested in “clean rooms and high-tech plant facilities” for a long period of time, and has been awarded 44 patents at domestic and abroad, and has published hundreds of papers in professional SCI journals. Mr. Hu has been teaching for 24 years and has systematically trained professionals in high-tech plant facilities technology in Taiwan.

Mr. Hu specializes in contamination control of high-tech plants and equipment. His patents have changed the shortcomings of traditional semiconductor process equipment, improved production yields, and advanced the process of wafer fabrication, and he is an expert in wafer carriers for semiconductor front-end processes in Taiwan, as well as an international authority in contamination control. His cooperation with TSMC and domestic memory manufacturers has fully demonstrated his superiority in micro-pollution control technology, which has enabled Taiwan to occupy an important position in the international arena in the field of micro-pollution control for semiconductor plants and equipment.

Mistakenly enrolled in the Mechanical Engineering Department, showing the passion for learning.

Mr. Hu came from a traditional rural family and was interested in learning from a young age. His parents were farmers and had limited financial resources, so he relied on public schooling to get his doctorate in order to reduce the family's expenses. In the 1970s, when higher education was not widely available, Mr. Hu was fortunate to graduate from junior high school and enroll in the Junior College of the Taipei Institute of Technology, which had an open culture and no hair ban. “Compared to other schools with strict discipline, Taipei Institute of Technology had a relatively free environment, where I could think about my future plans in addition to the knowledge in books, which had a great impact on the development of my personality traits in the future.”

It was actually a mistake for him to enroll in the Mechanical Engineering Department at Taipei Institute of Technology. At that time, Mr. Hu and his father went to the school to register for the distribution, and since the introduction started with the Mechanical Department, he was not clear about the application-based admission and the order of his aspirations at that time, so he put mechanical engineering as his first aspiration, but he could not change what he had already filled in, and so he entered the Mechanical Department. Even though it was a mistake, Mr. Hu is still passionate about mechanical engineering, and he believes that no matter what subject you study, as long as you are willing to put in the effort, you will be rewarded.

Design of clean rooms Establishment of negative pressure isolation ward standards

After graduating from Taipei Technical College, Mr. Hu went to Auburn University in the United States to study mechanical engineering, and after obtaining his M.S. degree in engineering, he returned to Taiwan and worked in the Thermal Fluid Technology Group of the Energy and Resources Research Institute of the Industrial Technology Research Institute (ITRI), where he began to work in the field of clean room design and pollution control for semiconductor manufacturing processes. In the 1990s, Taiwan's semiconductor industry took off, and major wafer fabs began to set up in full swing. TSMC's first fab was located at ITRI, and Mr. Hu was fortunate to have experienced that golden ages and had access to the early generation of semiconductor fabs.

“The concept of clean room was not very clear to the technology companies at that time, although I thought that clean room design had unlimited business opportunities,” said Hu. Soon after, there was an engineering company that had made a mistake in the flow field of the clean room, and if it could not be accepted, it would face a huge amount of compensation. Mr. Hu spent three months to help the company design the most suitable clean room.

With this successful case, Mr. Hu's reputation in the park has been established, and more and more manufacturers are seeking for consultation. As he was deeply impressed by the close relationship between the construction of the clean room and the building's electrical and mechanical equipment, he decided to go abroad to study for a doctoral degree at the University of Liverpool in the United Kingdom. In 1998, he returned to the National Taipei University of Technology (NTUT) to take up a teaching position because he was grateful for his alma mater's nurturing.

In 2003, when the SARS epidemic broke out in Taiwan, he helped the Bureau of Disease Control (BDC) to draw up safety standards for biosafety level 2 laboratories, and built biosafety level 2 negative pressure laboratories in 18 hospitals in Taiwan, and the negative pressure laboratories built at that time were even more useful during the global pandemic of the Coronavirus Disease in recent years.

Active Investment in Talent Cultivation Successful Opening of New Business Opportunities

Mr. Hu has long been involved in the research of “clean room and high-tech plant facilities”, which covers the pollution control of semiconductor wafer carrier automated transportation equipment, as well as the design of clean room and plant facilities. He has been working with manufacturers to develop clean room technology for high-tech factories for more than 20 years, and has established industry-academia cooperation technology alliances with 30 manufacturers in the past seven years. He has been awarded 44 patents and published hundreds of papers in professional SCI journals, and has also led the university-level “Center for Cleanroom Technology Research (CCTR)” and the “Semiconductor Plant and Process Equipment R&D Center” in the Prospect Technology Headquarters, which have a profound impact on the competitiveness of the semiconductor manufacturers by assisting in the development of clean rooms. In addition, Mr. Hu has been actively involved in the cultivation of talents in the field of cleanroom technology by regularly organizing “Short-term Training Courses on Cleanroom Technology”, which has trained more than 2,500 trainees and contributed greatly to the education of the society.

In recent years, Mr. Hu's research focuses on “microdyeing control solutions for high-end semiconductor manufacturing”, optimization of semiconductor wafer carrier equipment, technology unique at home and abroad, through patents to change the shortcomings of the traditional semiconductor wafer carrier, not only to improve the production yield, but also to successfully promote the progress of the wafer process, becoming the standard equipment for high-end semiconductor manufacturing process, creating nearly 500 million Taiwan dollars in output value, becoming a successful example of technology transfer on the industry-academia cooperation, and also open up a new business model for the domestic manufacturers.

Although Taiwan's semiconductor technology is very strong, the market share of Taiwan manufacturers in the front-end process equipment industry is only 5%, which is still on the low side, said Mr. Hu modestly. In recent years, Mr. Hu has cooperated with domestic companies such as TSMC, UMC, Macronix, Winbond, NTC, PSMC, etc., and at the same time, he has cultivated a lot of new blood in science and technology, which has indirectly made National Taipei University of Technology well-known in the park.

Grateful to his wife for her dedication

Mr. Hu believes that there are always setbacks and difficulties in his work, but his passion for nurturing talent and promoting research is what keeps him going. Mr. Hu recalls that in 1987, when he was still an assistant professor, he often traveled between Hsinchu and Taichung to attend the semiconductor clean room design credit class. Since the class was held from 6:30 to 9:30 p.m., it took a lot of time to commute to the class. He was deeply impressed by one time when the passenger bus he took on the way back had a fire accident, and he had to wait for help on the side of the road, which was a very dangerous situation, and it was midnight when he got home, but he didn't feel hard at all.

Mr. Hu's passion for academics is evident to his wife.“When I gave birth to my first child, although he came to the hospital to be with me during the delivery, he continued to work on the small table in the delivery room with his laptop. In addition, once when we had a gathering with friends and relatives, he learned that someone was decorating a new home, and he enthusiastically gave professional advice on the fluid mechanics of air-conditioning, which, although it looks like an occupational disease, is a demonstration of his enthusiasm for academia.”

In Mr. Hu's academic career, the person he is most grateful to is his wife. “My wife has been the most important pillar of support for me all along the way. In addition to her busy schedule at work, she also takes care of my three children, and I sincerely thank her for her selfless dedication. Of course, I also have to thank my parents, who have given everything to me without complaint or regret. In addition, I have always been very grateful to all the teachers and former colleagues of ITRI who have educated me. In fact, I am a very nostalgic person, and I keep close contact with the schools and organizations where I have stayed before.” Although he is seen as a workaholic, Mr. Hu's sentimental words show the delicate side of his heart.

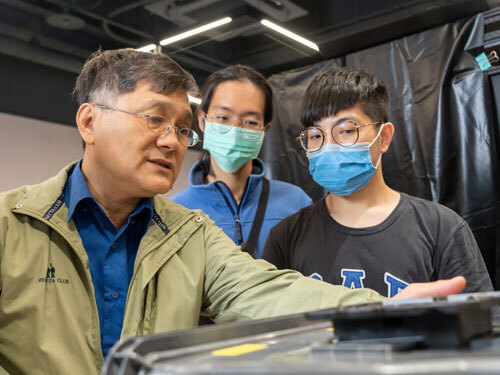

Mr. Hu is passionate about academics and has a lot of experience working with the industry, so he often reminds us that we should not slack off,” said Mr. Lai, a student in the Master's II class. Mr. Lai added, “We can discuss any difficulties in class with our teacher, who not only does his best to support us in doing experiments, but also provides us with subsidies for snacks, and he always says, 'Don't go hungry because of doing experiments.'”

Calling on the Government to Nurture Talents to Enhance Industrial Competitiveness

Currently, Mr. Hu's lab cooperates with universities in Japan and the U.S.A., and the patents he develops are often challenged by other countries. Therefore, his students are equipped with English language skills, patent thinking, and layout at the same time, and Mr. Hu believes that only in this way can they be considered to have international competitiveness. It is gratifying to see that Mr. Hu's credit class has produced many students who are now in charge of plant operations or clean rooms at major semiconductor factories. He is honored to see his students helping customers solve engineering problems, shining in various fields, and leading Taiwan's semiconductor industry to gain a foothold in the international arena.

In the future, Mr. Hu will focus on the development of environmentally friendly, ESG (environmental protection, social responsibility, and corporate governance) renewable chemical filters, in the hope of significantly reducing waste and carbon emissions to create waste reduction benefits. In addition, Mr. Hu will also set up the “Semiconductor Plant Facilities and Process Equipment R&D Platform Alliance” to utilize existing R&D technologies to develop complete solutions for pollution control of semiconductor key equipment and components, and to assist partner companies in obtaining a leading edge in technology and increasing the rate of self-manufacturing of semiconductor equipment.

For those who want to join the professional field in the future, Mr. Hu gives advice from his own experience, “The semiconductor industry is an industry that emphasizes innovation and professionalism. Although Taiwan has fewer resources than other large countries, we have been able to develop a very unique industry in this small country. Even though my field (plant/clean room and process equipment) only accounts for a small portion of the semiconductor industry, it is still Taiwan's strength. Taiwan should expand the cultivation of semiconductor process equipment and plant personnel, and there is still a big gap between supply and demand, which requires the government's support and cooperation in order to accelerate the development and competitiveness of this field.”